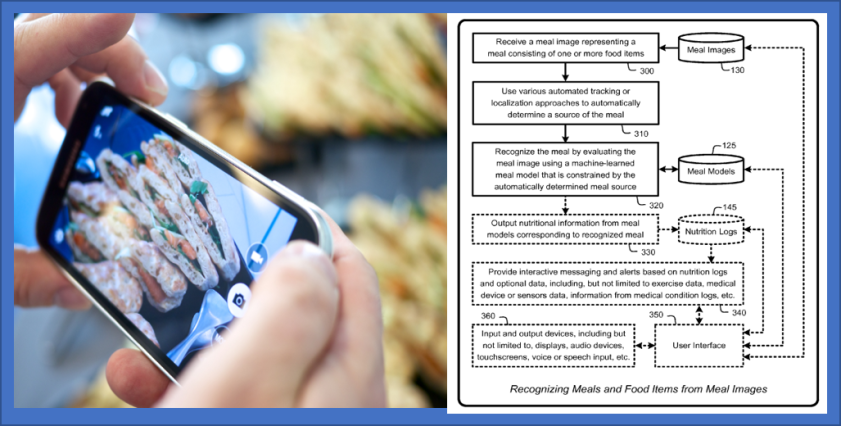

In my last blog I discussed the newly patented Microsoft Food Logging technology which will soon allow me to photograph the Thai curry on my dinner plate and help me log my caloric intake. Today I would like to introduce a similar concept but this time to capture the food at the beginning of the supply chain well before it reaches my plate. Instead of calculating calories, this new technology uses the images to calculate quality metrics.

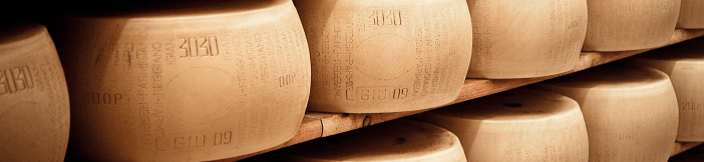

Before the steamed rice hit my dinner plate, the rice had been grown, harvested, processed, and packaged. During the processing at the rice mill the rice was continuously checked for various quality parameters including grain size and damage. Consumers today expect large, beautiful whole grains of rice, not broken discolored pieces.

Currently, quality control is cumbersome, as it requires samples to be sent to a lab and manually analyzed using calipers to measure length, scales to measure weight as well as visual inspection to discern color and cracks. These tests are often performed by several quality engineers in succession and can take hours to complete. This often results in delays as the grains cannot be further processed until the results are verified.

Building on the power of artificial intelligence, this quality process can be drastically simplified. Bühler, a Swiss grain processor announced at Microsoft Ignite last week that they are employing Artificial Intelligence to analyze grains in a fraction of the time it currently takes a quality engineer. By using a smartphone app, the engineer can take a photo of the rice and upload it to the Microsoft cloud for instant analysis.

As demonstrated in the above image, the painstaking manual analysis is replaced with a simple click. The photo is then analyzed using Microsoft intelligent cloud technologies and presented to the user in an easy-to-read graphic.

With 480 million metric tons of rice being consumed annually worldwide, a low cost and objective solution built on the power of AI increases efficiencies and maximizes yield.

For more information on the Bühler and Microsoft solutions, click here.

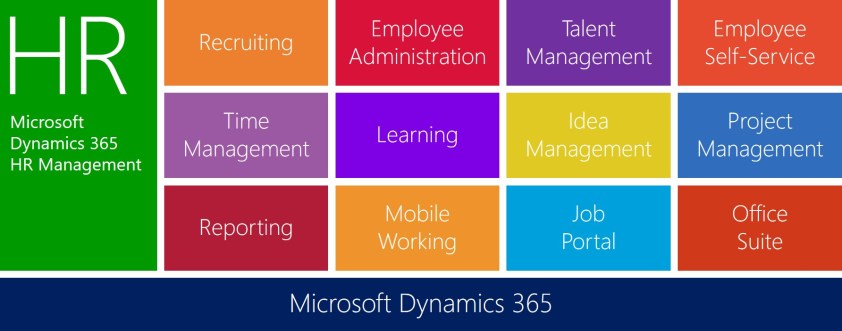

In under a few minutes we have researched the product we intend to purchase, received directions to our next purchase, used a coupon and made our purchase. The customer experience was simple, fast and hassle-free. No lines, no mess no fuss. Soon, this will be just a normal trip to the grocery store.

In under a few minutes we have researched the product we intend to purchase, received directions to our next purchase, used a coupon and made our purchase. The customer experience was simple, fast and hassle-free. No lines, no mess no fuss. Soon, this will be just a normal trip to the grocery store.

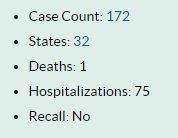

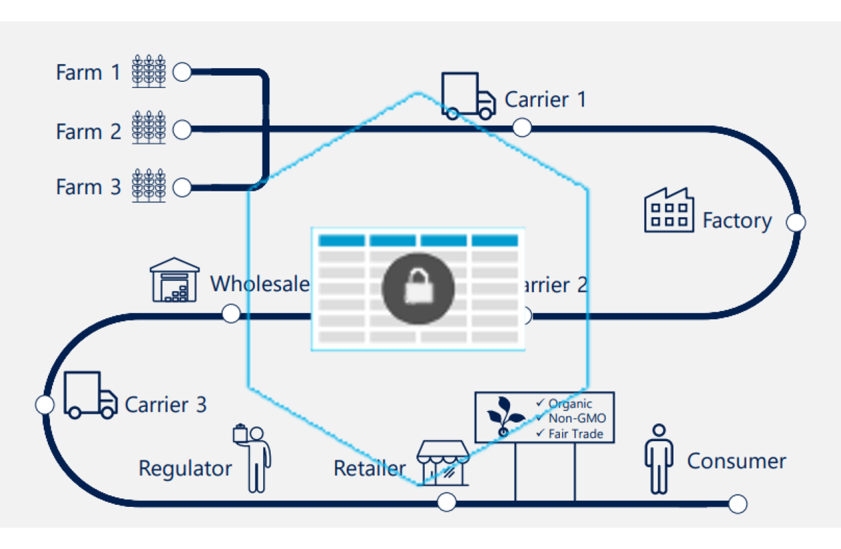

I wondered why the CDC would recommend such a drastic action and not just perform a recall to determine the source of the E. coli. From what I can surmise the distributor is

I wondered why the CDC would recommend such a drastic action and not just perform a recall to determine the source of the E. coli. From what I can surmise the distributor is

90% accuracy in formula management is not enough.

90% accuracy in formula management is not enough.